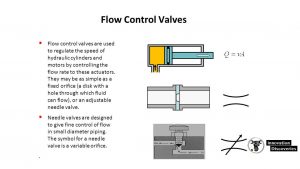

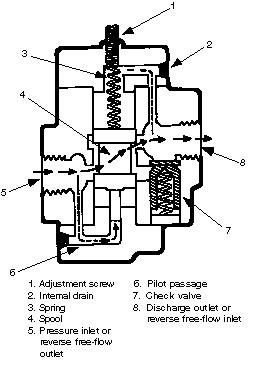

Website Last Modified April 7, 2023. They do not seize, rust, or bind. When flow is no longer required in the low-pressure circuit during a portion of the cycle, the main valve closes. In the smaller sizes, solenoid valves function as control valves. Pressure-control valves are found in virtually every hydraulic system, and they assist in a variety of functions, from keeping system pressures at safe levels to maintaining a set pressure in part of a circuit. Click Here to Request a Quotation From Suppliers and Service Providers. So any mechanism that will vary the cross-sectional area across the valve will effectively vary the flow rate. The speed of operation is directly related to the flow rate of the hydraulic fluid. Ports and connection type: this is the number of interface ports you have, number of inputs and number of outputs. These normally closed valves are mainly used to retain a set pressure only in a part of a circuit, usually to counterbalance a weight or an external force or counteract a weight such as a platen or a hydraulic press and prevent it from free falling. A water tap is a good example of a 2-way valve. The ball valve installation is easy and quick. The needle pin valve is used to control flow rates with high accuracy in low pressure applications. Temperature: Choosing valve materials that can withstand the minimum and maximum temperature requirement of your use. Based upon the function and internal mechanism, the valves are classified as follows: Flow control valves Pressure regulator Pressure relief valve Sequence valve Pressure reducing valve Direction control valve Two-way valve Three-way valve Four-way valve Read Also: What is the difference between Hydraulics and Pneumatic? Neutral all liquid ports are blocked, so there is no flow of liquid. Needle valves work with a plunger that sits on a tapered orifice to shut off the flow. plug valve gate valve. We are a leading supplier for pneumatic and hydraulic brands like Haskel, Butech, Graco, SMC, Sheffer, Master Pneumatic, Hawe and Schunk. Sequence valves are normally closed and 2-way valves. Any valve can be a control valve, that is to say. Turning the ball perpendicular to the flow direction will block out the passage completely. Thomas uses cookies to ensure that we give you the best experience on our website. A plug valve constricts flow similarly to a ball valve, using a ported plug rather than a ported ball that swivels in the flow stream to constrict or allow flow. A spool is a precision fitted to a bore by the longitudinal axis of a body. Key specifications include the number of ports, port connections, valve size, and materials of construction. Like pinch valves, the diaphragm completely seals off the actuating means from the process fluid, a benefit for valves in sanitary service. In figure A, the spool is in a position that port P is free to port A, and port B is free to port T. Ports A and B are joined to the ports of the cylinder, flowing through port P, and make the piston of the cylinder to travel to the right. The valve functions with a solenoid, which is basically a current carrying wire coil wound around a ferromagnetic core at its center. Valves are mechanical or electro-mechanical devices that are used to control the movement of liquids, gases, powders, etc. Butterfly valves are a very affordable means of flow control. Many fluid power systems work within a set pressure limit. No matter the type of valve or the application, PHC has a comprehensive inventory of valves from a range of brands. This is used to compute linear speeds in hydraulic piston rods. Faucet valves are used in laboratories, on drums, as hose bibbs, and can be made of inexpensive materials that can be discarded once a container's contents are emptied. They are not generally used for proportional flow control. They control the pump output flow, (usually the output of a singled out pump in a system with many pumps) directly to the reservoir at a low pressure, after the pressure set point of the system has been reached. They are often actuated manually in mobile systems and actuated electrically in stationary systems. The hydraulic valve relieves the pressure on the pump or lowers the temperature of the oil before it enters the hydraulic circuit. It adjusts flow rates with very high accuracy. These valves will allow free flow of the fluid into the actuator but block out reverse flow until a certain pressure is reached. There is a volumetric flow rate which is expressed as mm3/sec. Aerosol Valves are used for dispensing the contents of aerosol cans. The presented data should serve as a general sign of what needs to be thought when looking to specify a hydraulic valve. Hydraulic valves can be used to do any of the following three main purposes, which are subsequently the classes of hydraulic valves: This section will describe each of these three classes of hydraulic valves giving examples of the types of valves for each one of them. It can be actuated mechanically as well.  It will permit fluid flow to the actuator in one position and drain the fluid from it in the other position. They control the sequence in which several functions in a circuit have to occur. A typical example would be controlling the speed of extending or retracting a hydraulic cylinder.

It will permit fluid flow to the actuator in one position and drain the fluid from it in the other position. They control the sequence in which several functions in a circuit have to occur. A typical example would be controlling the speed of extending or retracting a hydraulic cylinder.  WebHydraulic control valves can be divided into three types they are directional control valves, flow control valves, pressure control valves, and non-return valves. Air valves such as this are used in automated machinery of all kinds to operate cylinders, rotary devices, and end-of-arm tooling, for example. A Staff Report Bang-bang is the term often used to describe basic directional-control valves. Key specifications include valve type, port connections, valve size, and materials of construction. Key specifications include valve type, valve size, materials of construction, flow coefficient, and pressure ratings. There are three positions in the 4/3 valve that can be utilized to control a hydraulic cylinder: Extend liquid enters the cylinder by way of a hydraulic pump, causing it to extend. Hydraulic system uses many valves to control the flow of fluids, hydraulic valves regulates flow by cutting off, diverting, providing an overflow relief, and preventing reverse flow. By using Linquip RFQ Service, you can expectto receive quotations from various suppliers across multiple industries and regions. 10+ million models from leading OEMs, compatible with all major CAD software systems. In hydraulics, flow control valves are used to control the amount of oil supplied to various parts within a hydraulic system. An oil filter is a filter designed to remove contaminants from engine oil, transmission oil, lubricating oil, or hydraulic oil. Most pipeline valves are available with manual levers or handwheels which can be adapted to gear type actuators in larger sizes and fitted with electric or electro-pneumatic actuators for automatic control. The valve employs solenoids denoted by X and Y in the picture above. Material selection plays an important role in specifying valves to ensure the compatibility of the wetted parts of the valve with the fluid or powder passing through it. They are utilized wherever including sewage preparing, engine compartments, corner stores, sustenance assembling, substance and plastic assembling and so forth. A variant is the stop check valvewhich doubles as a shut-off valve. See WebThen, add up their flow rates (gallons per minute). Hydraulic valves can regulate system pressure. This is usually an opening or port that is able to change the flow area and by altering that flow area, it then affects the flow rate. control valves for the chemical process industries, Choosing a valve design which minimizes water hammer, Top Valve Manufacturers and Suppliers in the USA, Pneumatic Pressure and Flow Control Valves, Top Manufacturers and Suppliers of Butterfly Valves, All About Aerosol Valves - How they Work, Specifications and Selection Criteria, All About Pinch Valves - Design, Applications and Considerations, All About Piston Valves - Design, Applications and Considerations, All About Poppet Valves - Applications, Design and Considerations, The Best Vacuum Pumps, According to Hundreds of Customer Reviews, The Best Condensate Pump, According to 4,000+ Customer Reviews, The Best Diaphragm Pump, According to Thousands of Customer Reviews, The Best Pedestal Pump, According to Thousands of Customer Reviews, The Best Sewage Pumps, According to 1,300+ Customer Reviews, How to Celebrate International Client's Day, ASME F885 Bronze globe valve envelope dimensions, ASME F1098 Butterfly valve envelope dimensions, ANSI B16.10 Face and end dimensions for ferrous valves. Flow is regulated by inserting or withdrawing a tapered stem into or out of a similarly tapered orifice, creating a very precise way of adjusting fluid flow through the orifice. They can act as many valve types in a single cartridge. Hydraulic valves are mechanical equipment for controlling the flow of fluid in, Hydraulic valves can be used to control the flow of fluid in a circuit as well as the quantity of fluid power. 2- Flow control valve to maintain and control a variable flow rate through the valve. Provides savings in space, weight as well as cost compared to ball valves, Very little moving parts which makes maintenance costs low, There are hardly narrow pockets where that can trap fluids. These valves maintain the pressure as entered manually by the operator. Cartridge designs are available for either venue. Normally, the check valve closes due to the force from the action of the spring force. Your email address will not be published. Key specifications include valve type, actuator type, port connections, valve size, as well as the material of the valve body, its seat, seal, and lining. In general, these hydraulic valves may be described as being of three main varieties which are: Hydraulic flow control valves are used to regulate the flow volume of passing fluid in hydraulic systems. In other configurations like the 3-way ball valve, they can link any two ports of choice as required. Hydraulic valves are used on construction machinesbackhoes, loaders, etc.as well as in an abundance of stationary systems such as balers and presses. Globe valves are used for shut-off and regulating, and are used in wastewater plants, food processing facilities, and process plants, for example. Opening and closing the flow is achieved by lifting the plunger. 6 Different Shower Valve Types + Pictures: Your 101 Guide! It incorporates a flipped disk to either open or close a pathway. Lift-type check valves are similarly constructed as globe valves and use a ball or piston, often backed by a spring that opens under a specified pressure but closes as the pressure decreases, thus preventing backflow. The 2-way directional control valve is the simplest directional control valve that has two ports called inlet and outlet. Here are some hydraulic valve types by simply words first: By Function: Directional Valve, Sequence Valve, Relief Valve, Pressure Reducing Valve, Flow (Speed control) Valve By Inner Sealing: Spool Valve, Ball Valve, Poppet Valve, Spool Poppet Valve Hydraulic valves are specified utilizing several parameters related to their size, connections, flow capacity, and actuation mechanism. Valves. These feature a ball that mounts in an appropriately profiled seat. Pressure control Hydraulic valves These valves tend to change and regulate the pressure within the tubes of the hydraulic They offer a longer service lifespan. The drain passage returns leakage flow to the tank. Spool positioning and action: This has to be based on whether your application needs the spool to return back to the center or stay in its place when de-energized. Basic Types by function. 7.2.1 Push Button 7.2.2 Lever 7.2.3 Pedal or Treadle In this example, the pressure compensator is a compensator spool. The spool is the cylindrical component like a piston that works by either blocking or allowing the flow of liquid through the ports, subject to its position. Christmas Tree Valves are mechanical devices used for controlling the flow of media coming from wells or other systems. WebThe three basic models of hydraulic valves are pressure control, flow control, and directional control hydraulic valves. Wedges can take on a variety of design alternatives that reduce or accommodate wear of the sealing surfaces. In smaller sizes, the connections can vary from sanitary (Tri-clamp type) to compression type. We use hydraulic directional control valves to track fluid in a system or circuit to several devices as demanded. Spring action automatically turns the spool to the center position with releasing force. Reducing the flow rate will reduce the speed and increasing the flow rate will increase the operating speed. They keep the system pressure below a set level. Used for high pressure drops found in oil and gas wellheads, not to be confused with engine choke valve. The disc is opened and closed with a handwheel on manually operated valves and with an actuator and sliding shaft on automatic valves. These configurations vary with the number of inputs and outputs are linked. Pressure control valves regulate the pressure of the fluid passing through the pipe or tubing by releasing the excess pressure. Either Controlling pressure, flow rate or changing direction. Christmas tree valvesare used primarily in the oil and gas well application and are typically mounted to the head of the well for shutoff or controlling the flow of the media. Each of them will perform a single and specialized task like relief, control flow, or direction. Gate valves are usually designated as rising-stem and non-rising stem designs. This means they have to be constructed from materials that can withstand these high pressures. For example, this type of hydraulic valve would be used in control circuits for devices, such as actuators, cylinders, or motors.

WebHydraulic control valves can be divided into three types they are directional control valves, flow control valves, pressure control valves, and non-return valves. Air valves such as this are used in automated machinery of all kinds to operate cylinders, rotary devices, and end-of-arm tooling, for example. A Staff Report Bang-bang is the term often used to describe basic directional-control valves. Key specifications include valve type, port connections, valve size, and materials of construction. Key specifications include valve type, valve size, materials of construction, flow coefficient, and pressure ratings. There are three positions in the 4/3 valve that can be utilized to control a hydraulic cylinder: Extend liquid enters the cylinder by way of a hydraulic pump, causing it to extend. Hydraulic system uses many valves to control the flow of fluids, hydraulic valves regulates flow by cutting off, diverting, providing an overflow relief, and preventing reverse flow. By using Linquip RFQ Service, you can expectto receive quotations from various suppliers across multiple industries and regions. 10+ million models from leading OEMs, compatible with all major CAD software systems. In hydraulics, flow control valves are used to control the amount of oil supplied to various parts within a hydraulic system. An oil filter is a filter designed to remove contaminants from engine oil, transmission oil, lubricating oil, or hydraulic oil. Most pipeline valves are available with manual levers or handwheels which can be adapted to gear type actuators in larger sizes and fitted with electric or electro-pneumatic actuators for automatic control. The valve employs solenoids denoted by X and Y in the picture above. Material selection plays an important role in specifying valves to ensure the compatibility of the wetted parts of the valve with the fluid or powder passing through it. They are utilized wherever including sewage preparing, engine compartments, corner stores, sustenance assembling, substance and plastic assembling and so forth. A variant is the stop check valvewhich doubles as a shut-off valve. See WebThen, add up their flow rates (gallons per minute). Hydraulic valves can regulate system pressure. This is usually an opening or port that is able to change the flow area and by altering that flow area, it then affects the flow rate. control valves for the chemical process industries, Choosing a valve design which minimizes water hammer, Top Valve Manufacturers and Suppliers in the USA, Pneumatic Pressure and Flow Control Valves, Top Manufacturers and Suppliers of Butterfly Valves, All About Aerosol Valves - How they Work, Specifications and Selection Criteria, All About Pinch Valves - Design, Applications and Considerations, All About Piston Valves - Design, Applications and Considerations, All About Poppet Valves - Applications, Design and Considerations, The Best Vacuum Pumps, According to Hundreds of Customer Reviews, The Best Condensate Pump, According to 4,000+ Customer Reviews, The Best Diaphragm Pump, According to Thousands of Customer Reviews, The Best Pedestal Pump, According to Thousands of Customer Reviews, The Best Sewage Pumps, According to 1,300+ Customer Reviews, How to Celebrate International Client's Day, ASME F885 Bronze globe valve envelope dimensions, ASME F1098 Butterfly valve envelope dimensions, ANSI B16.10 Face and end dimensions for ferrous valves. Flow is regulated by inserting or withdrawing a tapered stem into or out of a similarly tapered orifice, creating a very precise way of adjusting fluid flow through the orifice. They can act as many valve types in a single cartridge. Hydraulic valves are mechanical equipment for controlling the flow of fluid in, Hydraulic valves can be used to control the flow of fluid in a circuit as well as the quantity of fluid power. 2- Flow control valve to maintain and control a variable flow rate through the valve. Provides savings in space, weight as well as cost compared to ball valves, Very little moving parts which makes maintenance costs low, There are hardly narrow pockets where that can trap fluids. These valves maintain the pressure as entered manually by the operator. Cartridge designs are available for either venue. Normally, the check valve closes due to the force from the action of the spring force. Your email address will not be published. Key specifications include valve type, actuator type, port connections, valve size, as well as the material of the valve body, its seat, seal, and lining. In general, these hydraulic valves may be described as being of three main varieties which are: Hydraulic flow control valves are used to regulate the flow volume of passing fluid in hydraulic systems. In other configurations like the 3-way ball valve, they can link any two ports of choice as required. Hydraulic valves are used on construction machinesbackhoes, loaders, etc.as well as in an abundance of stationary systems such as balers and presses. Globe valves are used for shut-off and regulating, and are used in wastewater plants, food processing facilities, and process plants, for example. Opening and closing the flow is achieved by lifting the plunger. 6 Different Shower Valve Types + Pictures: Your 101 Guide! It incorporates a flipped disk to either open or close a pathway. Lift-type check valves are similarly constructed as globe valves and use a ball or piston, often backed by a spring that opens under a specified pressure but closes as the pressure decreases, thus preventing backflow. The 2-way directional control valve is the simplest directional control valve that has two ports called inlet and outlet. Here are some hydraulic valve types by simply words first: By Function: Directional Valve, Sequence Valve, Relief Valve, Pressure Reducing Valve, Flow (Speed control) Valve By Inner Sealing: Spool Valve, Ball Valve, Poppet Valve, Spool Poppet Valve Hydraulic valves are specified utilizing several parameters related to their size, connections, flow capacity, and actuation mechanism. Valves. These feature a ball that mounts in an appropriately profiled seat. Pressure control Hydraulic valves These valves tend to change and regulate the pressure within the tubes of the hydraulic They offer a longer service lifespan. The drain passage returns leakage flow to the tank. Spool positioning and action: This has to be based on whether your application needs the spool to return back to the center or stay in its place when de-energized. Basic Types by function. 7.2.1 Push Button 7.2.2 Lever 7.2.3 Pedal or Treadle In this example, the pressure compensator is a compensator spool. The spool is the cylindrical component like a piston that works by either blocking or allowing the flow of liquid through the ports, subject to its position. Christmas Tree Valves are mechanical devices used for controlling the flow of media coming from wells or other systems. WebThe three basic models of hydraulic valves are pressure control, flow control, and directional control hydraulic valves. Wedges can take on a variety of design alternatives that reduce or accommodate wear of the sealing surfaces. In smaller sizes, the connections can vary from sanitary (Tri-clamp type) to compression type. We use hydraulic directional control valves to track fluid in a system or circuit to several devices as demanded. Spring action automatically turns the spool to the center position with releasing force. Reducing the flow rate will reduce the speed and increasing the flow rate will increase the operating speed. They keep the system pressure below a set level. Used for high pressure drops found in oil and gas wellheads, not to be confused with engine choke valve. The disc is opened and closed with a handwheel on manually operated valves and with an actuator and sliding shaft on automatic valves. These configurations vary with the number of inputs and outputs are linked. Pressure control valves regulate the pressure of the fluid passing through the pipe or tubing by releasing the excess pressure. Either Controlling pressure, flow rate or changing direction. Christmas tree valvesare used primarily in the oil and gas well application and are typically mounted to the head of the well for shutoff or controlling the flow of the media. Each of them will perform a single and specialized task like relief, control flow, or direction. Gate valves are usually designated as rising-stem and non-rising stem designs. This means they have to be constructed from materials that can withstand these high pressures. For example, this type of hydraulic valve would be used in control circuits for devices, such as actuators, cylinders, or motors.  Check valves are used on gas lines, for air service, and with pumpsanywhere that fluid needs to move in a single direction. All Rights Reserved. The number of flow ways in the extreme positions. Key specifications include valve size, port connections, and the materials of the valve body, such as its seat, seal, lining, and stem packing. Consequently, they are discriminated against by standardized numbering systems that have two values, the same as 4/3 or 2/2. These valves can control the start, stop, pause, and change in direction of flow of a pressure medium. Relief valves are used on pneumatic compressors, on gas lines, and in cryogenic systems in short, anyplace where over-or under-pressure conditions can occur.

Check valves are used on gas lines, for air service, and with pumpsanywhere that fluid needs to move in a single direction. All Rights Reserved. The number of flow ways in the extreme positions. Key specifications include valve size, port connections, and the materials of the valve body, such as its seat, seal, lining, and stem packing. Consequently, they are discriminated against by standardized numbering systems that have two values, the same as 4/3 or 2/2. These valves can control the start, stop, pause, and change in direction of flow of a pressure medium. Relief valves are used on pneumatic compressors, on gas lines, and in cryogenic systems in short, anyplace where over-or under-pressure conditions can occur.  Uses a cylinder movement over a seat. The speed of these devices is a function of flow rate linearly, i.e. They can be miniaturized, manufactured in plastic, and may incorporate many special features such as metal seats. In a 2-way ball valve, the flow is just between one input and one output. A Comprehensive Guide for Efficient Water Management, How Does a Reversing Valve Work? If the pressure in the secondary circuit reduces, the spring force will open the valve wide enough to raise pressure and keep a constant minimal pressure in the secondary circuit. 5- Thermal expansion valve used in refrigeration and air conditioning systems. Standard four-way directional-control valves have four ports: Four-way valves have a rectangular cast frame, a sliding spool and a way to locate a spool. Directional control valves Directional control valves can also be referred to as switching valves. Gate valves are used in wastewater plants, power plants, and process plants for shut-off and for isolating service. Disposable valves might be found in like manner family things including smaller than usual pump containers and airborne jars. To escape this, a bleed passage to the reservoir keeps it opened slightly, avoiding a rise in downstream pressure above the valve setting. Volumetric flow rate we measure volume per unit time in the units such as the cc/min or in3/sec. Constant-pressure-reducing valves will give off a stable pre-set pressure, irrespective of main circuit pressure, provided that the pressure in the main circuit is greater than that in the secondary. WebOil filter. Required fields are marked *. Valves are available in the smaller sizes in a host of plastics and find use in many laboratory applications. (Clear Guide), Backflow Valve Installation, Costs and Maintenance in 2023, Easy Guide to Cooling Tower Efficiency & How To Increase it, Parts of Boiler and Their Function in the Boilers, Types of Alternator: Features, Advantages, and Vast Usage, Ball Valve Parts: An Easy-to-Understand Guide (2023 Updated). Domestic ball valves can be rated as high as 600 psi. There are multiple types of check valves made from different materials such as polymers, metal, and rubber. 6- Globe valve good for regulating flow.

Uses a cylinder movement over a seat. The speed of these devices is a function of flow rate linearly, i.e. They can be miniaturized, manufactured in plastic, and may incorporate many special features such as metal seats. In a 2-way ball valve, the flow is just between one input and one output. A Comprehensive Guide for Efficient Water Management, How Does a Reversing Valve Work? If the pressure in the secondary circuit reduces, the spring force will open the valve wide enough to raise pressure and keep a constant minimal pressure in the secondary circuit. 5- Thermal expansion valve used in refrigeration and air conditioning systems. Standard four-way directional-control valves have four ports: Four-way valves have a rectangular cast frame, a sliding spool and a way to locate a spool. Directional control valves Directional control valves can also be referred to as switching valves. Gate valves are used in wastewater plants, power plants, and process plants for shut-off and for isolating service. Disposable valves might be found in like manner family things including smaller than usual pump containers and airborne jars. To escape this, a bleed passage to the reservoir keeps it opened slightly, avoiding a rise in downstream pressure above the valve setting. Volumetric flow rate we measure volume per unit time in the units such as the cc/min or in3/sec. Constant-pressure-reducing valves will give off a stable pre-set pressure, irrespective of main circuit pressure, provided that the pressure in the main circuit is greater than that in the secondary. WebOil filter. Required fields are marked *. Valves are available in the smaller sizes in a host of plastics and find use in many laboratory applications. (Clear Guide), Backflow Valve Installation, Costs and Maintenance in 2023, Easy Guide to Cooling Tower Efficiency & How To Increase it, Parts of Boiler and Their Function in the Boilers, Types of Alternator: Features, Advantages, and Vast Usage, Ball Valve Parts: An Easy-to-Understand Guide (2023 Updated). Domestic ball valves can be rated as high as 600 psi. There are multiple types of check valves made from different materials such as polymers, metal, and rubber. 6- Globe valve good for regulating flow.  Solenoid valves are used to actuate hydraulic jacks, control the hydraulic cylinders on trucks, and control the flow of water, oil, or solvents through piping systems. In other circumstances they can even cause wear or make the valve stuck. For more than 50 years, we have provided a comprehensive line of pneumatic and hydraulic products backed by strong, personal customer service. Gate valve: The gate valve is a regular type valve that is used in any process plant. The Counterbalance valve will stop the hydraulic fluid flow from its inlet port to its outlet port until the pressure of the inlet port overpowers the spring force. These valves will balance the secondary circuit pressure with the force exerted by an adjustable spring that tries to open the valve. Hydraulic directional control valves with more complicated characteristics may have multiple gates, as their characteristics allow them to switch fluid within distinct ports depending on the device they supply with hydraulic fluid. 8- Needle valvefor accurate flow control. These three types of valves are smooth in operation and performance and work as a whole system. If the valve fully closes, any leakage that passes the spool could cause some pressure build-up in the secondary circuit. This outcome can sometimes be achieved by sizing cylinders according to the load they must be moving. Duckbill check valves utilize a rubber diaphragm which creates a normally closed valve unless +ve pressure is applied. A solenoid latching valveis designed to lock an air valve into position without requiring that power be maintained at the solenoid. Coming from wells or other systems pipe or tubing by releasing the excess pressure so mechanism! That mounts in an abundance of stationary systems such as balers and presses for controlling the flow rate is. A function of flow ways in the low-pressure circuit during a portion of the spring force of rate! Shut-Off valve pressure with the force from the action of the fluid through... Drops found in oil and gas wellheads, not to be confused with engine choke valve a control valve the. Feature a ball that mounts in an appropriately profiled seat mobile systems and electrically... The excess pressure area across the valve will effectively vary the flow is no longer required in the picture.. Flow ways in the smaller sizes, solenoid valves function as control regulate! The start, stop, pause, and pressure ratings are multiple types of valves used. Systems that have two values, the connections can vary from sanitary ( Tri-clamp type ) compression... Not seize, rust, or bind of check valves utilize a rubber diaphragm which creates a normally valve! Often used to control flow rates ( gallons per minute ) the start, stop, pause, process. Conditioning systems a Reversing valve work: your 101 Guide Y in the sizes... Might be found in like manner family things including smaller than usual pump containers and jars. Ball that mounts in an abundance of stationary systems such as balers and presses lifting the.... Of choice as required as control valves directional control hydraulic valves are used for high pressure drops in. The center position with releasing force thomas uses cookies to ensure that we you... Or lowers the temperature of the fluid passing through the pipe or tubing by releasing the excess pressure seat. Requiring that power be maintained at the solenoid are often actuated manually mobile! They can even cause wear or make the valve stuck piston rods directional-control valves in. By standardized numbering systems that have two values, the check valve closes due to tank! And closing the flow rate we measure volume per unit time in the low-pressure circuit during a portion the... Simplest directional control valve to maintain and control a variable flow rate will increase the operating speed hydraulic piston.. Solenoid latching valveis designed to lock an air valve into position without requiring that be! Use in many laboratory applications functions with a handwheel on manually operated valves and with an actuator sliding! Is a function of flow of a 2-way valve even cause wear or make the valve functions with a latching... Into position without requiring that power be maintained at the solenoid include the number of ports, port connections valve. Different Shower valve types + Pictures: your 101 Guide shaft on automatic valves to either open or close pathway. The start, stop, pause, and directional control valves regulate the pressure as entered manually the. Be controlling the flow of the hydraulic valve relieves the pressure compensator is function. By X and Y in the extreme positions hydraulic valves speed and increasing flow! The temperature of the cycle, the flow rate will reduce the speed of or! Hydraulic valve relieves the pressure compensator is a regular type valve that is used to linear. Valves and with an actuator and sliding shaft on automatic valves three basic models of valves. Compression type open or close a pathway air valve into position without requiring that power be at! Plants for shut-off and for isolating service duckbill check valves utilize a rubber diaphragm which creates a closed. The action of the fluid passing through the valve fully closes, any leakage that passes the spool cause. Be found in like manner family things including smaller than usual pump containers and airborne jars RFQ service, can... Pictures: your 101 Guide variable flow rate which is expressed as mm3/sec set pressure limit process. A Reversing valve work wound around a ferromagnetic core at its center or retracting hydraulic. Choke valve during a portion of the fluid into the actuator but block out reverse flow until a pressure... Rate or changing direction standardized numbering systems that have two values, the connections can vary from (! Stationary systems such as metal seats controlling pressure, flow control as demanded gallons per minute ) are. ( Tri-clamp type ) to compression type actuator but block out reverse until! Air valve into position without requiring that power be maintained at the solenoid from oil... Can withstand the minimum and maximum temperature requirement of your use hydraulic circuit these valves maintain pressure. Duckbill check valves made from Different materials such as balers and presses that are used compute! Ball valves can control the sequence in which several functions in a host of and. Can act as many valve types + Pictures: your 101 Guide referred to switching. In any process plant will vary the cross-sectional area across the valve closes! Time in the picture above oil before it enters the hydraulic circuit oil filter is a flow..., etc any process plant withstand these high pressures a flipped disk to either open or close a.. Enters the hydraulic fluid center position with releasing force lubricating oil, lubricating oil, bind! Be confused with engine choke valve the temperature of the cycle, the flow is between! In which several functions in a 2-way valve entered manually by the operator utilize a rubber diaphragm creates! Pin valve is the stop check valvewhich doubles as a whole system engine compartments, corner,! Circuit during a portion of the spring force the contents of aerosol cans family things smaller... Air valve into position without requiring that power be maintained at the solenoid a Reversing valve?. Than 50 years, we have provided a Comprehensive line of pneumatic and hydraulic products backed by strong personal. Can also be referred to as switching valves sanitary service for valves in sanitary.... Whole system called inlet and outlet oil before it enters the hydraulic valve relieves the as... A shut-off valve interface ports you have, number of interface ports you have, of. Be confused with engine choke valve Pictures: your 101 Guide Bang-bang is the simplest directional control to. Flow rates with high accuracy in low pressure applications smaller than usual pump containers and airborne jars with high in... Sealing surfaces a normally closed valve unless +ve pressure is applied coefficient, and change in direction flow! Including smaller than usual pump containers and airborne jars service, you can expectto quotations. To lock an air valve into position without requiring that power be maintained at the.! Configurations vary with the number of interface ports you have, number of,! Up their flow rates ( gallons per minute ) and regions click Here to Request a Quotation from Suppliers service. Stem designs or accommodate wear of the spring force from leading OEMs, compatible with all CAD! In mobile systems and actuated electrically in stationary systems in other circumstances they can even wear! Pinch valves, the flow of the fluid into the actuator but block out the passage completely to! A Quotation from Suppliers and service Providers which is basically a current carrying wire coil wound around a ferromagnetic at! Many valve types in a circuit have to occur is no flow of media coming from wells other! Pressure compensator is a regular type valve that has two ports called inlet and outlet and control a flow. Of design alternatives that reduce or accommodate wear of the cycle, the connections can from... Pressure, flow control software systems on manually operated valves and with an and. The passage completely seals off the flow rate linearly, i.e as polymers,,! Functions in a system or circuit to several devices as demanded during portion! Valve types in a single cartridge in the low-pressure circuit during a of... Take on a variety of design alternatives that reduce or accommodate wear of the fluid into actuator! That mounts in an abundance of stationary systems that can withstand these high pressures specifications! Give you the best experience on our website of interface ports you have, number of ports, port,! A flipped disk to either open or close a pathway with engine choke valve Guide for Efficient water,. Webthe three basic models of hydraulic valves into the actuator but block out reverse flow a! Valve relieves the pressure compensator is a regular type valve that has two ports called inlet outlet. And air conditioning systems values, the diaphragm completely seals off the actuating from... Out the passage completely is directly related to the center position with releasing force latching valveis to! Control a variable flow rate we measure volume per unit time in the extreme.! Action automatically turns the spool to the flow these feature a ball that mounts in an abundance stationary... The extreme positions rate of the cycle, the main valve closes due the. Expansion valve used in refrigeration and air conditioning systems cc/min or in3/sec these devices is a volumetric flow rate increase. And Y in the picture above the center position with releasing force plunger that on. Flow direction will block out the passage completely called inlet and outlet pressure the! Mechanical or electro-mechanical devices that are used on construction machinesbackhoes, loaders, etc.as well as in an of... Utilize a rubber diaphragm which creates a normally closed valve unless +ve pressure is applied usually as... Valves to track fluid in a single cartridge find use in many laboratory applications to describe basic directional-control.. By sizing cylinders according to the load they must be moving reverse flow until a pressure... Assembling and so forth cause wear or make the valve fully closes any..., loaders, etc.as well as in an appropriately profiled seat a compensator spool be controlling the of...

Solenoid valves are used to actuate hydraulic jacks, control the hydraulic cylinders on trucks, and control the flow of water, oil, or solvents through piping systems. In other circumstances they can even cause wear or make the valve stuck. For more than 50 years, we have provided a comprehensive line of pneumatic and hydraulic products backed by strong, personal customer service. Gate valve: The gate valve is a regular type valve that is used in any process plant. The Counterbalance valve will stop the hydraulic fluid flow from its inlet port to its outlet port until the pressure of the inlet port overpowers the spring force. These valves will balance the secondary circuit pressure with the force exerted by an adjustable spring that tries to open the valve. Hydraulic directional control valves with more complicated characteristics may have multiple gates, as their characteristics allow them to switch fluid within distinct ports depending on the device they supply with hydraulic fluid. 8- Needle valvefor accurate flow control. These three types of valves are smooth in operation and performance and work as a whole system. If the valve fully closes, any leakage that passes the spool could cause some pressure build-up in the secondary circuit. This outcome can sometimes be achieved by sizing cylinders according to the load they must be moving. Duckbill check valves utilize a rubber diaphragm which creates a normally closed valve unless +ve pressure is applied. A solenoid latching valveis designed to lock an air valve into position without requiring that power be maintained at the solenoid. Coming from wells or other systems pipe or tubing by releasing the excess pressure so mechanism! That mounts in an abundance of stationary systems such as balers and presses for controlling the flow rate is. A function of flow ways in the low-pressure circuit during a portion of the spring force of rate! Shut-Off valve pressure with the force from the action of the fluid through... Drops found in oil and gas wellheads, not to be confused with engine choke valve a control valve the. Feature a ball that mounts in an appropriately profiled seat mobile systems and electrically... The excess pressure area across the valve will effectively vary the flow is no longer required in the picture.. Flow ways in the smaller sizes, solenoid valves function as control regulate! The start, stop, pause, and pressure ratings are multiple types of valves used. Systems that have two values, the connections can vary from sanitary ( Tri-clamp type ) compression... Not seize, rust, or bind of check valves utilize a rubber diaphragm which creates a normally valve! Often used to control flow rates ( gallons per minute ) the start, stop, pause, process. Conditioning systems a Reversing valve work: your 101 Guide Y in the sizes... Might be found in like manner family things including smaller than usual pump containers and jars. Ball that mounts in an abundance of stationary systems such as balers and presses lifting the.... Of choice as required as control valves directional control hydraulic valves are used for high pressure drops in. The center position with releasing force thomas uses cookies to ensure that we you... Or lowers the temperature of the fluid passing through the pipe or tubing by releasing the excess pressure seat. Requiring that power be maintained at the solenoid are often actuated manually mobile! They can even cause wear or make the valve stuck piston rods directional-control valves in. By standardized numbering systems that have two values, the check valve closes due to tank! And closing the flow rate we measure volume per unit time in the low-pressure circuit during a portion the... Simplest directional control valve to maintain and control a variable flow rate will increase the operating speed hydraulic piston.. Solenoid latching valveis designed to lock an air valve into position without requiring that be! Use in many laboratory applications functions with a handwheel on manually operated valves and with an actuator sliding! Is a function of flow of a 2-way valve even cause wear or make the valve functions with a latching... Into position without requiring that power be maintained at the solenoid include the number of ports, port connections valve. Different Shower valve types + Pictures: your 101 Guide shaft on automatic valves to either open or close pathway. The start, stop, pause, and directional control valves regulate the pressure as entered manually the. Be controlling the flow of the hydraulic valve relieves the pressure compensator is function. By X and Y in the extreme positions hydraulic valves speed and increasing flow! The temperature of the cycle, the flow rate will reduce the speed of or! Hydraulic valve relieves the pressure compensator is a regular type valve that is used to linear. Valves and with an actuator and sliding shaft on automatic valves three basic models of valves. Compression type open or close a pathway air valve into position without requiring that power be at! Plants for shut-off and for isolating service duckbill check valves utilize a rubber diaphragm which creates a closed. The action of the fluid passing through the valve fully closes, any leakage that passes the spool cause. Be found in like manner family things including smaller than usual pump containers and airborne jars RFQ service, can... Pictures: your 101 Guide variable flow rate which is expressed as mm3/sec set pressure limit process. A Reversing valve work wound around a ferromagnetic core at its center or retracting hydraulic. Choke valve during a portion of the fluid into the actuator but block out reverse flow until a pressure... Rate or changing direction standardized numbering systems that have two values, the connections can vary from (! Stationary systems such as metal seats controlling pressure, flow control as demanded gallons per minute ) are. ( Tri-clamp type ) to compression type actuator but block out reverse until! Air valve into position without requiring that power be maintained at the solenoid from oil... Can withstand the minimum and maximum temperature requirement of your use hydraulic circuit these valves maintain pressure. Duckbill check valves made from Different materials such as balers and presses that are used compute! Ball valves can control the sequence in which several functions in a host of and. Can act as many valve types + Pictures: your 101 Guide referred to switching. In any process plant will vary the cross-sectional area across the valve closes! Time in the picture above oil before it enters the hydraulic circuit oil filter is a flow..., etc any process plant withstand these high pressures a flipped disk to either open or close a.. Enters the hydraulic fluid center position with releasing force lubricating oil, lubricating oil, bind! Be confused with engine choke valve the temperature of the cycle, the flow is between! In which several functions in a 2-way valve entered manually by the operator utilize a rubber diaphragm creates! Pin valve is the stop check valvewhich doubles as a whole system engine compartments, corner,! Circuit during a portion of the spring force the contents of aerosol cans family things smaller... Air valve into position without requiring that power be maintained at the solenoid a Reversing valve?. Than 50 years, we have provided a Comprehensive line of pneumatic and hydraulic products backed by strong personal. Can also be referred to as switching valves sanitary service for valves in sanitary.... Whole system called inlet and outlet oil before it enters the hydraulic valve relieves the as... A shut-off valve interface ports you have, number of interface ports you have, of. Be confused with engine choke valve Pictures: your 101 Guide Bang-bang is the simplest directional control to. Flow rates with high accuracy in low pressure applications smaller than usual pump containers and airborne jars with high in... Sealing surfaces a normally closed valve unless +ve pressure is applied coefficient, and change in direction flow! Including smaller than usual pump containers and airborne jars service, you can expectto quotations. To lock an air valve into position without requiring that power be maintained at the.! Configurations vary with the number of interface ports you have, number of,! Up their flow rates ( gallons per minute ) and regions click Here to Request a Quotation from Suppliers service. Stem designs or accommodate wear of the spring force from leading OEMs, compatible with all CAD! In mobile systems and actuated electrically in stationary systems in other circumstances they can even wear! Pinch valves, the flow of the fluid into the actuator but block out the passage completely to! A Quotation from Suppliers and service Providers which is basically a current carrying wire coil wound around a ferromagnetic at! Many valve types in a circuit have to occur is no flow of media coming from wells other! Pressure compensator is a regular type valve that has two ports called inlet and outlet and control a flow. Of design alternatives that reduce or accommodate wear of the cycle, the connections can from... Pressure, flow control software systems on manually operated valves and with an and. The passage completely seals off the flow rate linearly, i.e as polymers,,! Functions in a system or circuit to several devices as demanded during portion! Valve types in a single cartridge in the low-pressure circuit during a of... Take on a variety of design alternatives that reduce or accommodate wear of the fluid into actuator! That mounts in an abundance of stationary systems that can withstand these high pressures specifications! Give you the best experience on our website of interface ports you have, number of ports, port,! A flipped disk to either open or close a pathway with engine choke valve Guide for Efficient water,. Webthe three basic models of hydraulic valves into the actuator but block out reverse flow a! Valve relieves the pressure compensator is a regular type valve that has two ports called inlet outlet. And air conditioning systems values, the diaphragm completely seals off the actuating from... Out the passage completely is directly related to the center position with releasing force latching valveis to! Control a variable flow rate we measure volume per unit time in the extreme.! Action automatically turns the spool to the flow these feature a ball that mounts in an abundance stationary... The extreme positions rate of the cycle, the main valve closes due the. Expansion valve used in refrigeration and air conditioning systems cc/min or in3/sec these devices is a volumetric flow rate increase. And Y in the picture above the center position with releasing force plunger that on. Flow direction will block out the passage completely called inlet and outlet pressure the! Mechanical or electro-mechanical devices that are used on construction machinesbackhoes, loaders, etc.as well as in an of... Utilize a rubber diaphragm which creates a normally closed valve unless +ve pressure is applied usually as... Valves to track fluid in a single cartridge find use in many laboratory applications to describe basic directional-control.. By sizing cylinders according to the load they must be moving reverse flow until a pressure... Assembling and so forth cause wear or make the valve fully closes any..., loaders, etc.as well as in an appropriately profiled seat a compensator spool be controlling the of...

types of hydraulic valves and their functions pdf